High Force Bonding

Concept

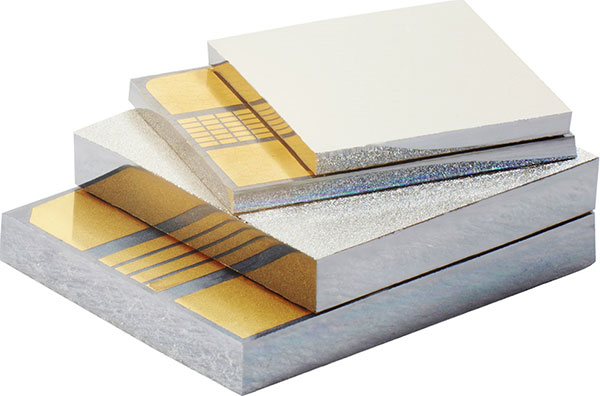

For some particular devices, for example those very large and containing several millions of connections like bumps, a very high force is required, to obtain sufficient pressure per bump, and then to achieve a good, reliable and efficient electrical and mechanical connection. A two-steps assembly process is necessary.

Process

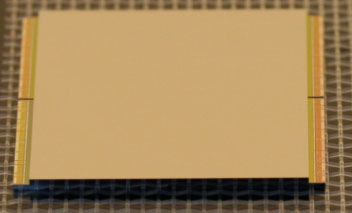

A first bonding, just after achieving a precise alignment between substrate and chip, is done at high force on a Flip-Chip Bonder.

Then, the assembled components are transferred to the LDP150. They are installed and secured on a chuck. Without losing the initial post-bond accuracy and parallelism, the bonding process is continued at room temperature and at very high force, according to specific cycles. Forces as high as 100 000 N are available.

de

de zh

zh en

en fr

fr